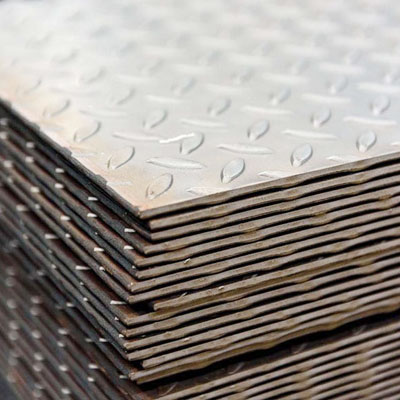

Steel Chequered Plates

Made to prevent skidding, chequered plate flooring is commonly found in factories and plants as well as roadways where skidding or sliding poses a risk. It takes its name from the distinct pattern that is heavily embossed into the uppermost layer of the metal. It looks like diamonds or checks, and in the US it is often described as diamond plate, and around the globe it can be referred to as tread plate and floor plate.

A lighter weight metal is often used for it, as it is applied over durable surfaces. Interestingly enough, its visual appeal is another reason that it appears in such places as interiors, vehicle tool boxes and treads where slipping is possible but also where the metallic and textural accent can add a nice element or touch. It is used industrially and commercially and is also a metal chosen for use in smaller workshops.

Steel chequered plate is available in thicknesses of:

- 3mm / 5mm / 6mm / 8mm / 10mm / 12mm / 20mm / 25mm

It is also available in lengths and widths from 1200 mm to 1500 mm, as well as custom lengths (typically ranging up to eight feet in length). It is found as an aluminum alloy and a steel product. Chequered carbon steel materials can be divided into the following grades and standards:

| A36 | Q195 |

| SS400 | Q 235 |

| SPCC | Q345 |

| SPHC | AH36 |

| A283 | A516 Gr.60/A516 Gr.70 |

| S235J1/S235J2/S235JR | ST37-2 |

| S275J1/S275J2/S275JR |

Chequered plate flooring is typically available with or without an angle frame and can be painted, hot dipped galvanized and self colored. When it is made of carbon steel, it comes self-coloured in solid black and will require coating to eliminate corrosion.

It is divided into three specific types and is also available in coils and sheets. The types include:

- Galvanized steel

- Chequered carbon steel

- Stainless

The galvanized chequered plate is technically hot dipped galvanized steel with a zinc coating. It is going to be rust resistant in even the wettest and dampest setting. It will offer corrosion resistance too and be one of the more affordable and decorative kinds of steel chequered plate. There is also the carbon steel which is always supplied with a coating and is a much more cost-effective option, though it may rust easily compared to the hot dipped, galvanized coils or panels.

Diamond or chequered plate is made using rolling processes, though the final rolling treatment is what embosses the distinct pattern into the plate. Flipping it to one side will reveal that the pattern is not pressed into the metal with molding but using a roller with the diamond pattern instead. For steel plates, this must be done with hot rolling, using a slab that is heated above its recrystallization temperature to prevent any changes in the mechanical properties of the material.

We are the leading exporter of steel chequered plates (i.e. diamond plate), and with top quality mills the European Union and Asia, it will be able to create the precise sizes and thicknesses you require, whether it is for walks and stairways in industrial areas or commercial ramps, outdoor fire exits where traction is essential, vehicles and trailers, pick-up beds and steps, toolboxes, accent areas on bumpers or trailers, steps on trailers or even for esthetic accents like those on architectural areas or specialized furnishings, you will be able to find precisely the right steel chequered plates.