Steel Hollow Sections

Crafted from coils and then pressed through dies, steel hollow sections can be in a variety of sizes. Regardless of their applications, they are measured by both interior and exterior dimensions and by wall thickness. Described as HSS in the United States, they are always made exclusively of structural steel per the specific code or standard. It is also known as tube steel because it is found in rounded forms as well as squares and rectangles. Though square, it always has rounded edges and in such places as the UK and Europe it is described by its shape rather than its hollowness. Acronyms like SHS, CHS or RHS will typically be in use, as well as metric rather than imperial measures.

Available as hot and cold rolled steel, they are most commonly used in the following designs:

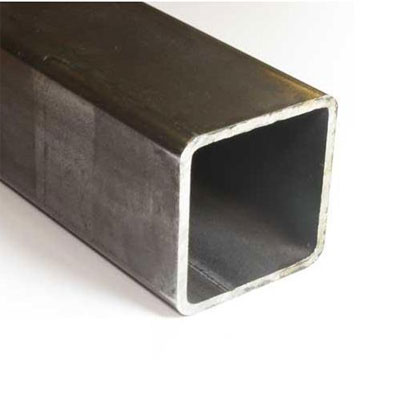

Square Hollow Sections

Typically made to A500 standards in Grade A, B, and C metals, they are also found as A513 and HSLA grades 50 and 70 sections. They are formed as squares or rectangular tubes through hot rolling and often called HSS or hollow structural sections. There is also an inside seam from welding in many of these sections and they are typically used to construct bicycle racks, home construction, and the building of trailers.

- Structural Hollow Sections (see above)

- Rectangular Tubes (see above) Used for the building of railings, truck frames and some construction processes.

Each of the sections above is described by its width x width x thickness. The variations are many with inches being used as a standard measurement. 5/8″ to 3/16 are considered the smallest measure for most, and outside dimensions can be as large as 32″x32″ or more.

Round Hollow Sections & Round Hollow Section Tubes

Also commonly employed for mechanical and structural purposes, they will typically be required to meet ASTMA 500 Grad B or UNS K 03000 standards for cold forming as well as HSLA 70 standards for tubing. This is similar to ASTM A500 Grade B, but has a higher strength capacity. When used for mechanical purposes, it will be required to conform to ASTM A513 Type 1(HR) or Type 2 (CR) standards. Dimensions are based on exterior diameter and wall thickness with 20″ among the largest sizes and .625 the thickest. Round hollows can also be as small as .12 inches in thickness and 1.660″ in diameter.

Mild Steel Black ERW Square

A hot rolled product that will have to conform to ASTM A53 standards, it is used for building scaffolding and industrial projects. It is the result of hot rolling processes and will be in a range of grades from 201,202,304,316,321,303,316L,310S,2205, to 904L. It can be found in 5.5mm to 500mm sizes and meet AISI, DIN, EN and other standards.

Steel hollow sections is a term used mostly in the United States and often summed as HSS, though other locations may not use this descriptor. They are typically for structural and mechanical application and can be produced in both hot and cold processes and to an enormous range of sizes. As one of the most efficient and versatile forms of construction, they are in high demand but must be as strong as buyers expect.

They can deliver a much higher strength to weight ratio than other materials, creating lighter and airier structures in general, but it is of the utmost importance that they be of the finest production qualities possible. We have a leading exporter of hollow sections that are crafted precisely to the buyer’s standards and specs. With top quality, the European Union and Asia, it will be able to create the precise steel hollow sections required for any sort of projects.